what is the development process of galvanized steel coil?

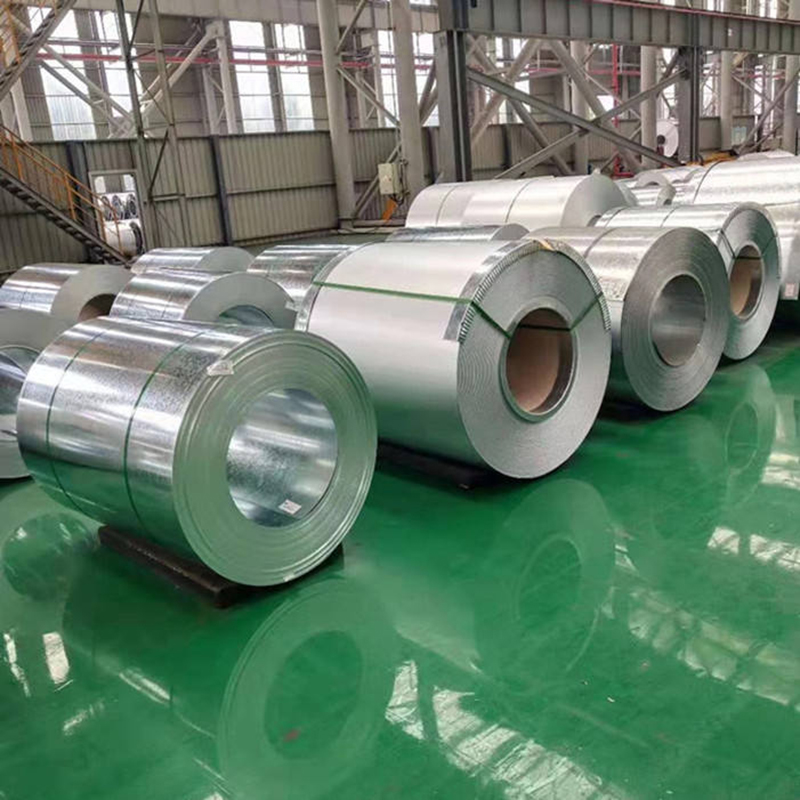

Galvanized Steel In Coil is widely used and has become an indispensable part of our life. The price of galvanized steel coil varies significantly, so it is very important to choose how to choose. What is the development history of gi steel coil?

l History of galvanized steel coil

lWhat is the production ofgalvanized steel coil?

lHow to identify the quality ofgalvanized steel coil?

History ofgalvanized steel coil

The history of galvanizing goes back more than 300 years. That’s when an alchemist and chemist came up with a reason to dip clean iron into molten zinc and create a gleaming silver coating on the iron. This will be the main step in the origin of the galvanizing process.

In 1836, Sorel of France filed several patents for this steel coating process by dipping steel in hot-melt zinc after the first cleaning. He gave the method the name “galvanizado”. Interestingly, Sorel was aware of the electrochemical nature of corrosion and therefore the role of zinc coatings on iron.

What is the production ofgalvanized steel coil?

1. Hot dip galvanizing can be a unique process. When stainless steel is immersed in molten zinc, a series of zinc-iron alloy layers are formed through a metallurgical reaction between iron and zinc, providing a durable coating that is an integral part of the steel.

2. When the chemical reaction between the iron and zinc has nearly ceased, the item is squeezed out of the galvanizing bath, with free zinc on the outer layer, and the process is complete.

3. In fact, there is no boundary between steel and zinc, but rather a gradual transition through a series of alloy layers, resulting in a metallurgical bond.

4. Basically, galvanized steel is nothing more than steel coated with a layer of zinc. By placing the steel in a hot zinc bath in a process called “hot dip galvanizing,” the two metals are permanently bonded together, resulting in a more durable version of the metal.

How to identify the quality ofgalvanized steel coil?

1. Production raw materials: Most of the raw materials used in galvanized steel coils are galvanized steel sheets, and the quality of galvanized steel coils is also different. The galvanized steel sheets of many small steel mills are not up to standard, and the galvanized steel coils begin to crack within a few months. However, the galvanized coils produced by the big steel mills are of good quality. galvanized steel coils under normal use will show no problems in just a few months.

2. Thickness ofgalvanized steel coil: The thickness of galvanized steel springboard is directly related to the service life of galvanized steel coil. Generally, the thickness of galvanized steel coil is divided into 1.2mm and 1.5mm. If the construction period is longer, it is recommended that you choose thickened galvanized steel coils, which have a longer service life and are stronger.

3. The raw material of gi steel coil springboard is very important, but its production process is also very important. It will be directly related to the safety factor of the galvanized steel springboard.

Galvanized steel coil is ubiquitous and plays an important role in our daily life. It is used in construction, transportation, agriculture, power transmission and wherever good corrosion protection and long life are required.If you are looking for a supplier of high quality Galvanized Steel In Coils at a reasonable price , the Shandong Hongqi Material Co., Limitado. is a very good choice.